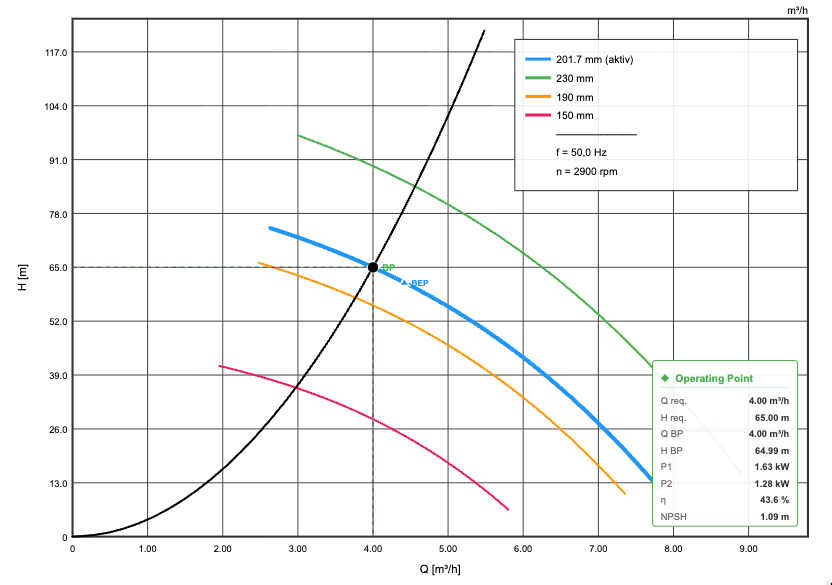

What Is Impeller Trimming?

In many industrial pump systems, centrifugal pumps do not operate at their optimal duty point.

The reason: the pump was sized for a design condition that is rarely reached in actual operation.

This is where impeller trimming comes in – the targeted machining or reduction of the impeller diameter to match the pump’s characteristics to the real demand.

Instead of wasting excess energy through throttle valves or bypass lines, impeller trimming reduces energy generation directly at the source.

The result: less wasted energy, lower operating costs, and a longer service life for the entire system.

Why Is Impeller Trimming Important?

Pumps are among the largest energy consumers in industry. Estimates suggest that around 20–25% of global industrial electricity consumption is attributable to pumping systems.

Many of these systems are oversized because engineers build in safety margins during design.

This means pumps constantly work against partially closed valves or throttle devices – an enormous waste of energy. Impeller trimming corrects this mismatch directly and sustainably.

10 Benefits of Impeller Trimming

Impeller trimming is a highly effective method for optimizing pump performance and reducing operating costs. By adapting the impeller diameter to actual system requirements, companies can significantly improve efficiency, reliability, and sustainability.

Significant Energy Savings

Reducing the impeller diameter lowers the pump’s power consumption disproportionately. According to the affinity laws, power scales with the cube of the diameter. Even a small impeller reduction can yield energy savings of 10–30%.

Reduced Operating Costs

Less energy consumption translates directly into lower electricity bills. For large pumps with long running hours, the investment often pays for itself within just a few months — making impeller trimming one of the most cost-effective optimization measures in fluid handling.

Elimination of Throttling Losses

Rather than destroying excess head through control valves or throttle devices, trimming ensures the energy is never produced in the first place. This eliminates the thermal and hydraulic losses caused by throttling — a clear gain for overall system efficiency.

Lower Mechanical Stress

An oversized pump generates higher radial forces, increased vibrations, and elevated axial thrust. Trimming moves the pump closer to its best efficiency point (BEP), significantly reducing mechanical loads on bearings, seals, and the casing.

Extended Component Lifespan

Lower vibrations and reduced hydraulic forces lead to less wear on bearings, mechanical seals, and other critical components. The result: longer maintenance intervals, fewer unplanned shutdowns, and higher overall equipment availability.

Reduced Noise and Vibration Levels

Pumps operating outside their optimal range produce noticeably more noise and vibration. Matching the impeller to actual operating conditions lowers noise levels, improving both the working environment and equipment protection.

Simple and Cost-Effective Implementation

Compared to a full pump replacement or installation of a variable frequency drive (VFD), impeller trimming is a relatively simple and affordable measure.

How It Works

The impeller is machined down or swapped for a smaller one — without extensive modifications to piping or controls.

8. Improved Process Stability

A pump running at its optimal duty point delivers more consistent pressure and flow rates. This enhances process stability and leads to better production outcomes — especially critical in the chemical, pharmaceutical, and food industries.

9. Contribution to Sustainability and CO₂ Reduction

Every kilowatt-hour saved reduces your company’s carbon footprint. Impeller trimming is an immediately effective measure for cutting energy consumption — a concrete step toward meeting your climate goals and ESG commitments.

10. Combinable with Other Optimization Measures

Impeller trimming pairs perfectly with other efficiency measures such as:

- Variable frequency drives (VFDs)

- Optimized piping layouts

- Condition monitoring systems

Together, they form a holistic optimization strategy that maximizes the economics of your entire pump system.

Conclusion – A Smart Step Toward Higher Efficiency

Impeller trimming is a proven, economical, and sustainable method for adapting pump systems to their actual operating conditions.

Whether it’s energy savings, wear reduction, or process optimization — the benefits are diverse and measurable. If your pumps are working against throttle valves or consistently running outside their optimal duty point, impeller trimming is the first step toward greater efficiency.